Mr. Green Scene

Member

Hi there, I'm Mr Green Scene but you-all can call me "G". I will be reporting on my rate of sucess growing in a micro-enviroment with LED panels.

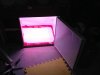

The panels I've obtained are 3x Haight Solid State PF-1600 grow LED's, in an enclosure I built that is 3x6x7. This considerably exceeds the manufacturers specification density of 4x4 per panel. I got a great deal on these panels, so I would like to give them a try this way, because they have gotten a bad rap so far.

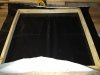

I started by framing a rear wall;

Then the side walls;

The front took a bit longer, framing up the openings for the doors;

Next I added a plywood panel for power, and hung the 700CFM bathroom fan I am using for venting;

A panel to carry the one-way louvered intake vent was installed, and the exhast fan plumbed into a nearby de-commisioned chimney.

At this point the entire enclosure was lined with Panda film. All seams were sealed with Tuck tape, duct tape was used to strengthen the staple locations;

The doors were glued and scewed together using finger jointed .5x1 stock, with Panda film stapled and taped to the wood frames. Cabinet Hinges were used to hang them, and weather stripping to create a seal;

More.5x1 stock was screwed to the inside flange of the rough opening, providing a gasket type seal with the weather stripping on the door. The exhaust fan being plumbed with 4" vent tubing, and the intake vent being plumbed with three inch, creates a negative preasure enviroment inside the enclosure when the fan is running. When it is not runnig, the enclosure is absolutely sealed so none of the smell escapes. Not in this picture the taunt Panda film, with the enclosure under preasure;

So please stick with me if your at all curious about the ability of the LED lights. As I've mentioned I'm pretty green at this with most of my experience 25 years old and currently irrelevant. I have already been helped by some great people here such as; Fried Rice, Thundercat, and more. I will definately be relying heavily on many of you who have more experience, so please don't heasitate to add your two cents to this thread..........I have big shoulders

Thanks again...................................."G".

The panels I've obtained are 3x Haight Solid State PF-1600 grow LED's, in an enclosure I built that is 3x6x7. This considerably exceeds the manufacturers specification density of 4x4 per panel. I got a great deal on these panels, so I would like to give them a try this way, because they have gotten a bad rap so far.

I started by framing a rear wall;

Then the side walls;

The front took a bit longer, framing up the openings for the doors;

Next I added a plywood panel for power, and hung the 700CFM bathroom fan I am using for venting;

A panel to carry the one-way louvered intake vent was installed, and the exhast fan plumbed into a nearby de-commisioned chimney.

At this point the entire enclosure was lined with Panda film. All seams were sealed with Tuck tape, duct tape was used to strengthen the staple locations;

The doors were glued and scewed together using finger jointed .5x1 stock, with Panda film stapled and taped to the wood frames. Cabinet Hinges were used to hang them, and weather stripping to create a seal;

More.5x1 stock was screwed to the inside flange of the rough opening, providing a gasket type seal with the weather stripping on the door. The exhaust fan being plumbed with 4" vent tubing, and the intake vent being plumbed with three inch, creates a negative preasure enviroment inside the enclosure when the fan is running. When it is not runnig, the enclosure is absolutely sealed so none of the smell escapes. Not in this picture the taunt Panda film, with the enclosure under preasure;

So please stick with me if your at all curious about the ability of the LED lights. As I've mentioned I'm pretty green at this with most of my experience 25 years old and currently irrelevant. I have already been helped by some great people here such as; Fried Rice, Thundercat, and more. I will definately be relying heavily on many of you who have more experience, so please don't heasitate to add your two cents to this thread..........I have big shoulders

Thanks again...................................."G".