You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LED DIY : Making of a "DJ SET "-style grow led light .

- Thread starter stardustsailor

- Start date

stardustsailor

Well-Known Member

Oh ...10 K pot !

But it will go down to 60 mA ! ....

But it will go down to 60 mA ! ....

stardustsailor

Well-Known Member

more trouble

with a 10k pot it seems that we can not drive the 3 Bucks. only way to find out is try.

otherwise we have to build our own Vref with more power, not a big problem

Why's that ? They seemed to work fine with the Bourns trimmer ,all three of them ...

stardustsailor

Well-Known Member

Now ..

Guod,I'm just working with what's available right now ...

Used the bourns trimmer (10 K ) ..

Kept the 1206 smd 180Ω one ...

And added to Vref one of 560 Ω ..

Total ~ 740 Ω ..

Current range went on 110 (min .) - 710 (max. ) mA ...

..

..

And they seem to work fine ....

But still min current has to go to 120mA ..

So ..

What would be the res ?

Should I try close to 1 K ?

Guod,I'm just working with what's available right now ...

Used the bourns trimmer (10 K ) ..

Kept the 1206 smd 180Ω one ...

And added to Vref one of 560 Ω ..

Total ~ 740 Ω ..

Current range went on 110 (min .) - 710 (max. ) mA ...

..

..And they seem to work fine ....

But still min current has to go to 120mA ..

So ..

What would be the res ?

Should I try close to 1 K ?

stardustsailor

Well-Known Member

Put 1.1 K res ..

Total resistance at Vref ~ 1200-1300 Ω ..

Pot at 10 K (10.000 Ω ) ...

Range is sweet now ...

140 mA - 710 mA ....

So ...Pot 10 K & res 1 K .

......

......

Flashback ... ;-P

( I wonder how on Earth ,those cheap Asian reds ,can withstand a current of 710 mA ,without a heatsink ...

Had them switched on about 5-8 min at 710mA ....

Each test string has 8-12 leds ....

...Their light is totally blinding,at 710 mA ...

Even if not directly looking at it ......)

Total resistance at Vref ~ 1200-1300 Ω ..

Pot at 10 K (10.000 Ω ) ...

Range is sweet now ...

140 mA - 710 mA ....

So ...Pot 10 K & res 1 K .

......

......Flashback ... ;-P

( I wonder how on Earth ,those cheap Asian reds ,can withstand a current of 710 mA ,without a heatsink ...

Had them switched on about 5-8 min at 710mA ....

Each test string has 8-12 leds ....

...Their light is totally blinding,at 710 mA ...

Even if not directly looking at it ......)

stardustsailor

Well-Known Member

Analog dimming offers really precise (reaaalllly ....depending on potentiometer ...Multi-turn ones ,offer greatest control ... ) of 0-100{+}% of power range ..

(whereas digital dimming has a power range of 10~90% ) ...

Ohh ..It needs an analog pin "read-out " ,to be "complete"...

(whereas digital dimming has a power range of 10~90% ) ...

Ohh ..It needs an analog pin "read-out " ,to be "complete"...

stardustsailor

Well-Known Member

Some news from "hot-plate " soldering ....

Still waiting for paste to arrive ...

Tried some times with "squeezed to flat " ordinary solder pieces and flux paste ..

Plastic asian type leds do not need preheating [increasement from 25° C to ~100/120 °C,at 2-3 °C/sec ] ,

neither do need "soaking " [ slow increase---0.5-1 C/sec ---- from ~100/120°C to 180/200°C ].

They have thermoplastic polymer body and lens

,not subject to cracking due to rapid temp change ,but way sensitive to prolonged heat ....

If preheat and /or "soaking" is/are applied to those kind /type of leds .

.they deform ...both body and lens ...

Best way to hot plate solder them at numbers ( i.e . x6 or x12 ,x24 ,ect ) is to have max setting on stove ,

put the mcpcb on ,see them as they solder and then take away quickly the pcb ..

final outcome is rather good ,with really smooth solder joints ..And without plastic polymer deformations ...

From the other hand ...

Quality leds ...(Cree/Osram/Luxeon/Ledengin,ect ) ...

They usually have a ceramic body (yes ,"ceramic" as like ordinary glass or pottery ,plates ,ect )

and hard silicon lens .. ( high temp resistant ) ..

Although ,the materials of those leds ,do not melt or deform under high -temps ,

they are wayyyyy- subject to "cracking " or "chiping " ,if their temperature changes dramatically ....

So they need prolonged preheating and " hot-bathing ",before they reach actual solder temperature .. (220-240 °C ) ..

And of course ,slow ramp down ,still left on hot-plate ,but with heat switched off ...

Until temp drops to around ~100 ° C ..

Then they can be removed from hot-plate ..

A thin layer of sand / thin sheet of ally ,make miracles on heat-spreading ...

Specially regarding ," ceramic plate kitchen stoves " ....

Still waiting for paste to arrive ...

Tried some times with "squeezed to flat " ordinary solder pieces and flux paste ..

Plastic asian type leds do not need preheating [increasement from 25° C to ~100/120 °C,at 2-3 °C/sec ] ,

neither do need "soaking " [ slow increase---0.5-1 C/sec ---- from ~100/120°C to 180/200°C ].

They have thermoplastic polymer body and lens

,not subject to cracking due to rapid temp change ,but way sensitive to prolonged heat ....

If preheat and /or "soaking" is/are applied to those kind /type of leds .

.they deform ...both body and lens ...

Best way to hot plate solder them at numbers ( i.e . x6 or x12 ,x24 ,ect ) is to have max setting on stove ,

put the mcpcb on ,see them as they solder and then take away quickly the pcb ..

final outcome is rather good ,with really smooth solder joints ..And without plastic polymer deformations ...

From the other hand ...

Quality leds ...(Cree/Osram/Luxeon/Ledengin,ect ) ...

They usually have a ceramic body (yes ,"ceramic" as like ordinary glass or pottery ,plates ,ect )

and hard silicon lens .. ( high temp resistant ) ..

Although ,the materials of those leds ,do not melt or deform under high -temps ,

they are wayyyyy- subject to "cracking " or "chiping " ,if their temperature changes dramatically ....

So they need prolonged preheating and " hot-bathing ",before they reach actual solder temperature .. (220-240 °C ) ..

And of course ,slow ramp down ,still left on hot-plate ,but with heat switched off ...

Until temp drops to around ~100 ° C ..

Then they can be removed from hot-plate ..

A thin layer of sand / thin sheet of ally ,make miracles on heat-spreading ...

Specially regarding ," ceramic plate kitchen stoves " ....

guod

Well-Known Member

makes me also wonder, recom says 0.2mA input current for Van. for 3 of them it´s 0.6mA, but the Vref can only deliever 0.5mA.

it seems that Van can work on lower input currrent.

maybe 0.2mA is worst case...

my Bucks also arrived today, they are good for 1.4A

View attachment 2542823

and i´m waiting for the Arduino Pico board (6 PWM channels, realtime Clock, etc)

...heliospectra here i come

and i will not use any Pots, the User-interface will be on a android tablet. spectrum at your fingertipps.

it seems that Van can work on lower input currrent.

maybe 0.2mA is worst case...

my Bucks also arrived today, they are good for 1.4A

View attachment 2542823

and i´m waiting for the Arduino Pico board (6 PWM channels, realtime Clock, etc)

...heliospectra here i come

and i will not use any Pots, the User-interface will be on a android tablet. spectrum at your fingertipps.

stardustsailor

Well-Known Member

Ohh ..It needs an analog pin "read-out " ,to be "complete"...

bargraph led

View attachment 2542875View attachment 2542876

Ehhh ..Pretty cool ,a led bar graph ...But kinda complicated to implement ...

While ....

Just an 20 K resistor was all what was needed ,for this analog pin read-out , to " behave " ...

Connected parallel ( as if "voltmeter" ) at Vref and An.Dim .

stardustsailor

Well-Known Member

Well .....

Hot-plate soldering the tiny Oslons,seemed a piece of cake ...

Covered the Oslons ,with some lenses from Asian cheapo leds ( !!! ) ,so to "mask" them ...

In order to spray the pcb ,with a circuit protective lacquer ...

Nice .....

Used some Arctic Silver Epoxy and 6x rivets (3 x 16 mm ) ,to attach mcpcb to heatsink ....

...

...

After that testing ,I was seeing 'green spots' ,all over .....

Way powerful leds ,those tiny Oslons ......

Box will be ready ,soon ...

Hot-plate soldering the tiny Oslons,seemed a piece of cake ...

Covered the Oslons ,with some lenses from Asian cheapo leds ( !!! ) ,so to "mask" them ...

In order to spray the pcb ,with a circuit protective lacquer ...

Nice .....

Used some Arctic Silver Epoxy and 6x rivets (3 x 16 mm ) ,to attach mcpcb to heatsink ....

...

...After that testing ,I was seeing 'green spots' ,all over .....

Way powerful leds ,those tiny Oslons ......

Box will be ready ,soon ...

guod

Well-Known Member

with rivets i would use grease, will be thinner than any epoxy.

as an idea on of the sides with epoxy the other with grease.

than you can checktemps with a multimeter by checking the Vf of the diodes.

which Vf is higher wll have a better performance.

to get the real die-temp. i use a similar way, but for this you need a fast sampling meter to get the Vf at start-up

google "led vf temperature"

as an idea on of the sides with epoxy the other with grease.

than you can checktemps with a multimeter by checking the Vf of the diodes.

which Vf is higher wll have a better performance.

to get the real die-temp. i use a similar way, but for this you need a fast sampling meter to get the Vf at start-up

google "led vf temperature"

stardustsailor

Well-Known Member

As soon as I'll finish it ...I'll do that ...

( I had one "mishappen" with one pcb ....Being stupid ,I haven't let the pcb enough on the solder temp ..

So some leds were flickering at low current ..(bad solder contact ..) ..So I had to take it out from heatsink ,to re-solder the leds

..(yes ,I'had already installed it ,before testing it ..

Stupid-stupip-stupid ...So ...The mcpcb ...had an "injury ",during the "removal surgery " ....Kinda bended a bit ..Maybe some parts of it ,won't be contacting the heatsink so good ...What the heck ,,,It's the first one ....Others will follow soon .....First I need to "learn " on that one ....

Oh ...No ..I'm not going to make a new mcpcb for those leds (and light box ...) ..Let them burn ,in joy !

....

This is a "sample "/ training box -project ....

..I'm just "warming up " for the "good " ones ! ........)

Anyway ....

Second pcb installed ..The third one ,for tomorrow .....

For now I 've to settle with a cheap pot of 10 K,until the "good" ones arrive ....

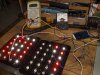

Pics taken with same manual settings ....( 2 different sets )

Range of dimming : 200-710 mA .

...

...

A good friend(and a led grower himshelf ) said :

" Shit ! That looks really right ,bro !

Like an August sun .... Ohhh...This looks way promising ...."

We'll see ...

Soon ..

As for the heatsink temps .....

Well after 15 min of working at 710 mA ..

(And one pcb ,being really ..a "flying carpet" (! ) over the heatsink ...)....

Heatsink ,was probably of lower than ambient temperature ..

Just freezing to touch ..

Really ...

Both mcpcbs ,were slightly warm ....

It's a bit noisy ...Sounds more like a "gamers modified pc " ..

But not in a level that can be "alarming " ...

But air-flow from both sides is MASSIVE ..

Freezing cold air ,is what the "exausts " are pumping out ..

(at least for 15 min at 710 mA ) ....

Also that "thermal copper pour design " seems really to work wonders !

(Osram uses "thermal copper pours " in some metal core pcb designs ..)

Cooling efficiency ,seems of highest level possible ...

(regarding forced air (active ) aluminium heatsink cooling ..)

..I'' test that also ,though ....

(Based on Vf ,as Guod suggested ...

Seems really a ...hm... cool way ..)

Edit : Weird ..This light now looks like a moon -shuttle from the late 60's....

" This is one small light for a man ....But a giant star for the plants ... "

( I had one "mishappen" with one pcb ....Being stupid ,I haven't let the pcb enough on the solder temp ..

So some leds were flickering at low current ..(bad solder contact ..) ..So I had to take it out from heatsink ,to re-solder the leds

..(yes ,I'had already installed it ,before testing it ..

Stupid-stupip-stupid ...So ...The mcpcb ...had an "injury ",during the "removal surgery " ....Kinda bended a bit ..Maybe some parts of it ,won't be contacting the heatsink so good ...What the heck ,,,It's the first one ....Others will follow soon .....First I need to "learn " on that one ....

Oh ...No ..I'm not going to make a new mcpcb for those leds (and light box ...) ..Let them burn ,in joy !

....

This is a "sample "/ training box -project ....

..I'm just "warming up " for the "good " ones ! ........)

Anyway ....

Second pcb installed ..The third one ,for tomorrow .....

For now I 've to settle with a cheap pot of 10 K,until the "good" ones arrive ....

Pics taken with same manual settings ....( 2 different sets )

Range of dimming : 200-710 mA .

...

...A good friend(and a led grower himshelf ) said :

" Shit ! That looks really right ,bro !

Like an August sun .... Ohhh...This looks way promising ...."

We'll see ...

Soon ..

As for the heatsink temps .....

Well after 15 min of working at 710 mA ..

(And one pcb ,being really ..a "flying carpet" (! ) over the heatsink ...)....

Heatsink ,was probably of lower than ambient temperature ..

Just freezing to touch ..

Really ...

Both mcpcbs ,were slightly warm ....

It's a bit noisy ...Sounds more like a "gamers modified pc " ..

But not in a level that can be "alarming " ...

But air-flow from both sides is MASSIVE ..

Freezing cold air ,is what the "exausts " are pumping out ..

(at least for 15 min at 710 mA ) ....

Also that "thermal copper pour design " seems really to work wonders !

(Osram uses "thermal copper pours " in some metal core pcb designs ..)

Cooling efficiency ,seems of highest level possible ...

(regarding forced air (active ) aluminium heatsink cooling ..)

..I'' test that also ,though ....

(Based on Vf ,as Guod suggested ...

Seems really a ...hm... cool way ..)

Edit : Weird ..This light now looks like a moon -shuttle from the late 60's....

" This is one small light for a man ....But a giant star for the plants ... "

stardustsailor

Well-Known Member

I ,by the power of truth ,while living ,I've conquered the universe ...

Many times ....(Or at least ...plenty ...)

Power of Truth : Not a mystical thing / " the Force " or something like that ....

Simple ...

Try to learn the truth behind everything ...

And the truth is one :

We are The One .

We are everything .

We can do everything .

What we dream (? ..dream ? )

...And more than that ...

...

Simple enough ...

Many times ....(Or at least ...plenty ...)

Power of Truth : Not a mystical thing / " the Force " or something like that ....

Simple ...

Try to learn the truth behind everything ...

And the truth is one :

We are The One .

We are everything .

We can do everything .

What we dream (? ..dream ? )

...And more than that ...

...

Simple enough ...

stardustsailor

Well-Known Member

Nooo...It's not that much noise,brother Guod ...

I'm sure most of it will be dimmed /dumpen by tent/room ...

And ,moreover ,I like the leds freezing to their ...best .....

(I pay total-absolute RESPECT to your design !

BEST DESIGN EVER ! ...

I will keep repeatin' that ,all the time ..

It's f@ckin' brilliant ! ..

See ,what I'm takin' about ?

It took just two persons ,unknown to each other ,never spoken to each other face to face ...

Forget the flesh ....Mind ( sssss) .....Two (and couple more helpin' ) minds ,built this light ...

Ok, the hands belonged to me ...Like Guods hands to him ....Like Chronicool's to him and so on for everybody ..

A small trivial detail ....

Cause ,I really trust ...If really wanted ? Everybody can build such and better light ...All it takes ,is to really bewish it ...Want it ..One has to really want it..The rest of the universe (i.e. Guod ,this ,that ... ) will conspire,so to become ....real ..)

I'm sure most of it will be dimmed /dumpen by tent/room ...

And ,moreover ,I like the leds freezing to their ...best .....

(I pay total-absolute RESPECT to your design !

BEST DESIGN EVER ! ...

I will keep repeatin' that ,all the time ..

It's f@ckin' brilliant ! ..

See ,what I'm takin' about ?

It took just two persons ,unknown to each other ,never spoken to each other face to face ...

Forget the flesh ....Mind ( sssss) .....Two (and couple more helpin' ) minds ,built this light ...

Ok, the hands belonged to me ...Like Guods hands to him ....Like Chronicool's to him and so on for everybody ..

A small trivial detail ....

Cause ,I really trust ...If really wanted ? Everybody can build such and better light ...All it takes ,is to really bewish it ...Want it ..One has to really want it..The rest of the universe (i.e. Guod ,this ,that ... ) will conspire,so to become ....real ..)

Similar threads

- Replies

- 46

- Views

- 7K

- Replies

- 16

- Views

- 5K