NoFucks2Give

Well-Known Member

That wheel has already been invented

Thanks for posting the photo of @wietefras fixture. He did a very good job. Those brass fitting are a bit pricey.

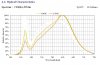

I've been running thermal experiments for months now, and found that thinner copper plates to mount the CoBs is better (less thermal resistance), clamping them to the pipe works better than solder, and the copper plate should be a minimum of 4" long along the pipe. I would do a 48" long 0.062" thick bar clamping it to the pipe on each side of the CoB and mount a CoB every 4". When my new milling machine arrives, I will make a custom plate to mount the CoB on the bar and the bar to the pipe with the same bracket.

With the bar clamped to the pipe with C-Clamps, in the pictured test setup, and running 11° C water through the pipe, the thermal pad temperate was 23° C and ambient room temp was 27° C.

With water at 27° C the thermal pad temp was 42° C.

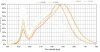

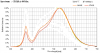

The reason I am working on this is because I want to use Deep Red LEDs and they are extremely sensitive to heat. I estimate most fixtures with red LEDs lose about 50% of their radiant flux to heat.