According to the site, the strips have 112 chips each.

View attachment 4357199

Your driver is outputting 10.4A, at 45V. When we look at the data sheet of the chips that the strips are made from we can start to put a picture together.

View attachment 4357198

Now for some deduction...

What we know...

10.4A ÷ 16 strips = 650mA each strip.

45V wired in parallel means each strip gets 45V.

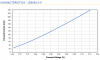

650mA is too much for each chip, the graph only goes to 240mA. So the strips have to further divide the 650mA into multiple smaller chunks. How many smaller chunks? Idk.. Let's find out...

650mA ÷ 3 chunks = 216mA per chunk.

112 chips divided into 3 chunks means 37.3 chips each chunk. You can't have uneven chips per string, so 3 chunks is not the right amount of chunks that the 650mA is divided into. So lets try another number.

650mA ÷ 4 chunks = 162.5mA per chunk

112 chips divided into 4 chunks means 28 chips per chunk. Ok so how many volts will 28 chips and 162.5mA need? Looking at the chart you can see that 162.5mA roughly corresponds to a Vf of ~2.99V for 1 chip, so 28 in series would be 83.72V and this is far over the 45V that you were measuring so 4 chunks isn't correct, let's try another guess.

650mA ÷ 6 chunks = 108.3mA per chunk

112chips divided into 6 chunks is 18.66 chips per chunk and we can't have uneven chips per string (or chunk) so the strips aren't dividing the current into 6 different chunks, time to try anther guess.

650mA ÷ 7 chunks = 92.8mA per chunk.

112 chips divided into 7 chunks means 16 chips per chunk. How many volts will 16 chips and 92.8mA need? Looking at the chart you can see that 92.8mA roughly corresponds to a Vf of ~2.83V for 1 chip, so 16 in series would be 45.28V and this is pretty spot on to what you're measuring. So it looks like 7 chunks probably.

^^^ This is why I'm saying that the driver is only pushing 45V. Its due to the design of the strips and the particular wiring of the setup. It means that while the load is connected your driver will only push ~45V to flow 10.4A, and may only bump up to ~45.5V to flow the max 11.01A. In order to see 48V while the load is connected, and assuming the strips are 16S7P, then it would require ~18.2A (and draw ~873W) and your driver can only do ~11A, so your max driver V is being limited by how much V the load actually needs in order to push the max driver current.

48V ÷ 16 chips per chunk = 3.0V per chip

3.0V corresponds to ~162.5mA, so 7 of these 162.5mA parallel chunks equates to one big chunk of 1,137.5mA. There are 16 strips in the light so if each strip were at 48V then each strip would flow 1,137.5mA or 1.137A and when that's added up it equates to 18.2A. DC Watts = V·A, so 18.2A × 48VDC = 873.6W, even using a 600h-48 wouldn't be big enough driver to push 48V in your setups.