PICOGRAV

Well-Known Member

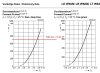

This is right, they might use anywhere from 38 volts up to 45 volts to pull that current, depending on temperature and age. You really do need the sense terminals connected yes, you will have no control over the voltage if you don't, with out them you are always in constant current and would be able to drive the LEDs but you would be, like driving them blind.For clarification, when looking for LED drivers. To run one Vero 29 I need 39v and 3.1a. To run two, Would I need 39v and 6.2a

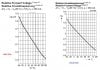

I think once the sense's are connected everything will become clear, proper adjustment should be like this, turn all the knobs counter clock wise to zero, first middle out the fine volt and amp adjustments. Next give the amp "Course" knob a quarter turn clock wise, then work your voltage up from the "Course" voltage knob until the LEDs illuminate, keep increasing the voltage until you hit the current limit set be the quarter turn on the amp knob, once the you hit the set current limit DONT increase the voltage yet, LEDs will be very dim at this point. What you would do now is go another quarter turn or maybe a little more with the amp knob and then increase the voltage again, keep doing this until you reach the correct amps. At this point bring back the current by turning the course current knob counter clock wise just until you are on the edge if the current/voltage limiter. Now you have a dialed in current and you should leave the current knobs alone for the rest of operation, you can dim with just the voltage, always bring the voltage up and give it about a quarter turn past the current limit, so it will take up the slack if the LEDs resistance drops.

I would not dial in the LEDs with the constant current control, its a much more rudimentary system compared to the way the voltage is regulated and you will see, jumps up and down quiet sporadically.

I think the fan should be replaced, if you want to do some extended tests, maybe take the old one out and mount a DC fan on the outside of the case with a small external power source, the cross flow air is needed to cool sensitive components of the Power Supply system.