You can get a boiling point chart under vacuum, that wont tell you what temp on the outside you need to feed it to keep it at lets say 44 on the inside over the course of an evap if that's what I think your looking for. People buy a vac oven for that sort of "set temp"

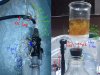

Qwizo were talking about the benefit's of using a water aspirator rather than a vacuum pump as the source of suction in a vacuum assisted filtration. An apirator uses the venturi force of water, the solvent exits the vac line into water rather than your pump oil. #2 when your able to distill, lab distill "not copper tube distill" you can "renature" your denature ethanol in minutes under vacuum. It's called pulling a forshot and anyone who's made ethanol knows the first thing to boil out will be methanol so throw away the first boil. Simple as that, your everclear I can't buy where I live cost you way more than the 1 litre of pure 2d ethanol cost me. I don't tell other people to do it though it's kinda of plain basic lab tek. As long as your 2d is pure 85% etoh 15% methanol you can never end up with methanol in your end product because it boils before ethanol does..... I happen to have glassware from steam distilling years ago, so once i bought a refridgerated cold trap that was the end of me loosing solvent.

Except for when im filtering i don't like running the cold trap so i let the methanol go out my vac line, it cost 40 bux and you put it on your sink, vac pump = protected......