New Experimental Advanced DIY Designs.

- Thread starter stardustsailor

- Start date

stardustsailor

Well-Known Member

stardustsailor

Well-Known Member

I'll have that in mind ...It serves also in more compact design ......(drivers outside ....)...

But since mains cable is going for the PSU of fans .....And FFS relay circuit ....

I think it has pretty adequate cooling ,though ........

Where's that "someone" to say his opinion about the whole blue-print design ?

Specially about cooling issues there ....

(After all this is part of his legasy .....Passed on to others,to continue ....Isn't that so ? )

BTW ..HIS design is ,maybe ,amongst the greatest-if not the best ... ....

Strong and simple enough ....

But since mains cable is going for the PSU of fans .....And FFS relay circuit ....

I think it has pretty adequate cooling ,though ........

Where's that "someone" to say his opinion about the whole blue-print design ?

Specially about cooling issues there ....

(After all this is part of his legasy .....Passed on to others,to continue ....Isn't that so ? )

BTW ..HIS design is ,maybe ,amongst the greatest-if not the best ... ....

Strong and simple enough ....

stardustsailor

Well-Known Member

oh,well....

Some great things begun as "sparks"...

As 'crazy ' ideas ...

Or just as plain , good ol' dreams ....

....

Eh...

"reality ' ...Doesn't stand far ,then .....

Who knows ...

Edit : All riveted parts(not moving ) are supposed to be glued together also with thermal conductive silicone ....

So .more or less ,this "tank " will act as a big alum heatsink ......

Also I think ,airflow is sufficient enough,for efficient cooling -at least ,for the amount of heat produced ,by both leds and drivers ,of this panel ........

Some great things begun as "sparks"...

As 'crazy ' ideas ...

Or just as plain , good ol' dreams ....

....

Eh...

"reality ' ...Doesn't stand far ,then .....

Who knows ...

Edit : All riveted parts(not moving ) are supposed to be glued together also with thermal conductive silicone ....

So .more or less ,this "tank " will act as a big alum heatsink ......

Also I think ,airflow is sufficient enough,for efficient cooling -at least ,for the amount of heat produced ,by both leds and drivers ,of this panel ........

RainerRocks

Active Member

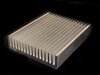

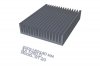

Get 2 of these awesome heatsinks which can be mounted many ways and

then just create the space needed for the drivers by spreading out the heatsinks. Yep this is what I'm going to buy plus the CREE LED's also fit this heatsink.

http://www.youtube.com/watch?v=K1GWV4liq2o

then just create the space needed for the drivers by spreading out the heatsinks. Yep this is what I'm going to buy plus the CREE LED's also fit this heatsink.

http://www.youtube.com/watch?v=K1GWV4liq2o

stardustsailor

Well-Known Member

Get 2 of these awesome heatsinks which can be mounted many ways and

then just create the space needed for the drivers by spreading out the heatsinks. Yep this is what I'm going to buy plus the CREE LED's also fit this heatsink.

http://www.youtube.com/watch?v=K1GWV4liq2o

Well...I've my " doubts" about this ...

- Osram Oslons ,are way better Warm white leds ,than Crees ...( Cree makes really good Cool Whites ,from the other hand ....)

-This modular heatsink system ,probably has it's " dark spots " there..

a) The Alum Alloy used seems of a hard alloy of the 7000 family of alloys or tempered 6000 alloys ....

(Same as in alum profiles for making windows,balcony doors ,ect ..)

Not very good thermoconductivity ....Not like pure alum or soft alloys.....Way inferior ...

b ) Some dimensions/specs of this " heatsink " are totally off ...

Like thickness base ( very thin ) ..

Lots of leds ,packed closely together ,in a heatsink with that thin base ?

Heat doesn't spread evenly to the fins ....Heat goes from led to heatsink fins without "spreading out " ..

Creating " Hot spots " ,at the heatsink ......

And behind this base ,thin and ' tall ' fins ?

(Also packed closely together ...)...

No-no-no-no.....

Also :" Fin efficiency is increased by decreasing the fin aspect ratio (making them thicker or shorter)....."

" To decrease the spreading resistance in the base of a heat sink:

-Increase the base thickness" .......

" Aluminium alloy 1050A has one of the higher thermal conductivity values at 229 W/m•K but is mechanically soft.

Aluminium alloys 6061 and 6063 are commonly used, with thermal conductivity values of 166 and 201 W/m•K, respectively.

The values depend on the temper of the alloy.

Material ,Fin efficiency,Spreading resistance & Fin arrangements.......

https://en.wikipedia.org/wiki/Heat_sink

http://www.kayelaby.npl.co.uk/general_physics/2_3/2_3_7.html

http://aluminium.matter.org.uk/content/html/eng/default.asp?catid=166&pageid=2144416529

Thanx,anyway ...

stardustsailor

Well-Known Member

Now ....Led protection ....

Have to protect leds somehow..

( Mainly from physical impact ,abrasion ,ect ....)

....Any ideas,that might fit to the current desing ,are more than welcome ...

...

....

Ok ....

-98 pcs Osram Oslons ....

( NW & Hyper RED wasn't the EVO 4 ? ..

2 x NW and 4 x reds ,if I remember correctly .....

Ok.....This one has 16 more warm Whites ,per module ... )

)

-High quality fans,drivers ,ect ...

-Protective circuits and fuses ....

(Stoney 'mistake' :colors of mains cables ,are "the other way around " connected ...

Where is blue cable -neutral-should be brown -phase/active-

and vice versa...)

....Hmm...

I kinda like the whole thing...

Seems ,appealing ...

(Cost of building such a thing ,from the other hand ,doesn't ....)

Have to protect leds somehow..

( Mainly from physical impact ,abrasion ,ect ....)

....Any ideas,that might fit to the current desing ,are more than welcome ...

...

....

Ok ....

-98 pcs Osram Oslons ....

( NW & Hyper RED wasn't the EVO 4 ? ..

2 x NW and 4 x reds ,if I remember correctly .....

Ok.....This one has 16 more warm Whites ,per module ...

-High quality fans,drivers ,ect ...

-Protective circuits and fuses ....

(Stoney 'mistake' :colors of mains cables ,are "the other way around " connected ...

Where is blue cable -neutral-should be brown -phase/active-

and vice versa...)

....Hmm...

I kinda like the whole thing...

Seems ,appealing ...

(Cost of building such a thing ,from the other hand ,doesn't ....)

RainerRocks

Active Member

Well...I've my " doubts" about this ...

- Osram Oslons ,are way better Warm white leds ,than Crees ...( Cree makes really good Cool Whites ,from the other hand ....)

-This modular heatsink system ,probably has it's " dark spots " there..

a) The Alum Alloy used seems of a hard alloy of the 7000 family of alloys or tempered 6000 alloys ....

(Same as in alum profiles for making windows,balcony doors ,ect ..)

Not very good thermoconductivity ....Not like pure alum or soft alloys.....Way inferior ...

b ) Some dimensions/specs of this " heatsink " are totally off ...

Like thickness base ( very thin ) ..

Lots of leds ,packed closely together ,in a heatsink with that thin base ?

Heat doesn't spread evenly to the fins ....Heat goes from led to heatsink fins without "spreading out " ..

Creating " Hot spots " ,at the heatsink ......

And behind this base ,thin and ' tall ' fins ?

(Also packed closely together ...)...

No-no-no-no.....

Also :

http://www.kayelaby.npl.co.uk/general_physics/2_3/2_3_7.html

http://aluminium.matter.org.uk/content/html/eng/default.asp?catid=166&pageid=2144416529

Thanx,anyway ...

Yes It's made of heatsink grade 6063 T5 aluminum which is also common for HS's . Plus it's very good for moisture resistance and better than some of the crap that comes in chinese fixtures.

The LEDs aren't packed together like the video..that's just for show..they are adjustable and can be glided on the slots and you put only as many LED'S as you need.

Pic of sink with specs but too small to see the fin size or spacing for my eyes. I sent off an email asking about Fins and base measurements.

http://www.ledgroupbuy.com/makersled-designer-heatsink-kit-professional-grade/

http://makersled.com/?page_id=24#material

Anyway you might get some ideas from it's many mounting options. It's good enough for me as I won't be using them high wattage LED's you are getting which need more thermal dissipation requirements.

I know your set-up is going to be great !

Anyway back to your thread.

stardustsailor

Well-Known Member

Yes It's made of heatsink grade 6063 T5 aluminum which is common for HS's also. The LEDs aren't packed together like the video..that's just for show..they are adjustable and can be glided on the slots and you put only as many LED'S as you need.

Pic of sink with specs but too small to see the fin size or spacing for my eyes.

http://www.ledgroupbuy.com/makersled-designer-heatsink-kit-professional-grade/

http://makersled.com/?page_id=24#material

Anyway you might get some ideas from it's many mounting options. It's good enough for me as I won't be using them high wattage LED's you are getting which need more thermal dissipation requirements.

I know your set-up is going to be great !

Anyway back to your thread.

T5 ? ..6063 is an aluminium alloy, with magnesium and silicon as the alloying elements. The standard controlling its composition is maintained by The Aluminum Association. It has generally good mechanical properties and is heat treatable and weldable. It is similar to the British aluminium alloy HE9.

6063 is mostly used in extruded shapes for architecture, particularly window frames, door frames, roofs, and sign frames. It is typically produced with very smooth surfaces fit for anodizing.

https://en.wikipedia.org/wiki/Aluminium_alloy

Thermal conductivity of 6063 T5 .... : 209 W/m-K-O Full soft (annealed)

-T Heat treated to produce stable tempers

-T1 Cooled from hot working and naturally aged (at room temperature)

-T2Cooled from hot working, cold-worked, and naturally aged

-T3 Solution heat treated and cold worked

-T4Solution heat treated and naturally aged

-T5 Cooled from hot working and artificially aged (at elevated temperature)

-T51 Stress relieved by stretching

-T510 No further straightening after stretching

-T511 Minor straightening after stretching

-T52 Stress relieved by thermal treatment

-T6 Solution heat treated and artificially aged

-T7 Solution heat treated and stabilized

-T8 Solution heat treated, cold worked, and artificially aged

-T9 Solution heat treated, artificially aged, and cold worked

-T10 Cooled from hot working, cold-worked, and artificially aged

http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA6063T5

Heatsinks we use ,are made here in Hellas .

(Big Alum producer ..)

Is made of (soft as butter ....) AA 1050 A alloy ....No temper ..( O ) .....

Relatively cheap as alloy ....(Almost pure Al ....) ..So soft ,that can't be used almost nowhere ....

But ....

Thermal conductivity of AA 1050 A O .... : 231 W/m-K

https://www.efunda.com/materials/alloys/aluminum/show_aluminum.cfm?ID=AA_1050&prop=all&Page_Title=AA 1050

It makes great heatsinks !

(though very soft ...Very easy to work with ..)

So ...I'd rather stay with that 4 lb chunks of soft ally,already existing ...

They 're rather great ..

( base thickness : 10 mm , 16 x thick fins of 30 mm 'height' ...>5 mm spaced )

PetFlora

Well-Known Member

Well the channels need to line up with your design. Does not appear precise enough for a Merkaba shapeGet 2 of these awesome heatsinks which can be mounted many ways and

then just create the space needed for the drivers by spreading out the heatsinks. Yep this is what I'm going to buy plus the CREE LED's also fit this heatsink.

http://www.youtube.com/watch?v=K1GWV4liq2o

RainerRocks

Active Member

You just stagger/spread out the LED's where ever you want on each line..no rule saying they have to line up.

stardustsailor

Well-Known Member

Go here ...

I think you'll like it ...

Cost ?

(I'm planning on actually making one or two of these panels ...

For testing them as prototypes ,at least ...)

I'd say about to 500-700 $ ......

(Well worth every single last penny ....

As most expensive and of highest quality materials used ....Even the smallest screw ..... )

I know that's much for 96 pcs of led panel ...

( from ~96 to ~192 Watts ,driving the SSLs from 350mA up to 700mA ,respectively )

But ....

...what this baby is cabable of - In real life- ,with that moderate amount of power,is another issue ...

To be seen ....

I think you'll like it ...

Cost ?

(I'm planning on actually making one or two of these panels ...

For testing them as prototypes ,at least ...)

I'd say about to 500-700 $ ......

(Well worth every single last penny ....

As most expensive and of highest quality materials used ....Even the smallest screw ..... )

I know that's much for 96 pcs of led panel ...

( from ~96 to ~192 Watts ,driving the SSLs from 350mA up to 700mA ,respectively )

But ....

...what this baby is cabable of - In real life- ,with that moderate amount of power,is another issue ...

To be seen ....

PetFlora

Well-Known Member

Sorry to be so late to respond. I unsubbed by accident. I had a big image, can't find it now. It would make a perfect panel. Hopefully, one of these will reveal how to expand Did you build it... and do you have a thread?Like I said, I'd like to start with more blue than I believe is needed so I can fine tune it myself. I won't say that I don't believe a warmer spectrum is the way to go (because I do), I felt that I needed to put myself through the paces (so to speak). I'd like to have my own grasp on these concepts, rather than what I gathered elsewhere.

I like NW in the center, it just makes sense. Although, I don't think I fully understand what you mean.

View attachment 2493354

Something along those lines?

EDIT:

View attachment 2493361