PSUAGRO.

Well-Known Member

The Nearest Ocean Is 2000 Miles Away Now What

NOW I know where you live pimp !!!

.................................haha

.................................hahaThe Nearest Ocean Is 2000 Miles Away Now What

.................................haha

.................................hahaPLUTONOW I know where you live pimp !!!.................................haha

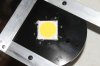

thats crazy man,you can almost count the dies in that pic,looks like a vero shit all over the back of that heatsink lolI have seen discoloration on COB side of pin heatsink that is exposed to air. Also saw discoloration under COB. You can even tell that cob I used on this one. Anodized layer has changed, takes a while with sandpaper to remove the anodized layer

View attachment 3889849

Have not seen any impact on Heatsinks/cob performance due to this discoloration.

I have seen similar discoloration on extruded heatsink for boards. Again on led board side on areas exposed to air. No discoloration on backside. It's odd because both sides of Heatsinks has same temps with the boards.

Happens over time even on heatsinks that run under 50C. Must be anodization black dye oxidizing.

That's quite a patina! Gives it that antiquated look. Maybe you can sell them on E bay as an Original Pin Heatsink, from the early Industrial Revolution, or something.Is Anyone Else Experiencing This Discoloring Of Their Heat Sinks

I'm Using Khatod 1825's On A 140mm Heat Sink Running My Cob At 80 Watts A Piece

View attachment 3888900

Hard anodizing produce 30 micron layer if you respect the righ time of the process, if you are under, near 5/10 micron, probably too fast process, and a thin layer in teory can do that type o damage on prolonged exposure to heat and light.They are using cheap black anodising that is not light fast so the light and heat make it fade.

I Concur below Is My Cxb 5000K Mother Light That Has Been Ran At 100 Watts 25 Watts Each For 24 Hours A Day For The 4 Months And No Discoloration. Its Does Show Sloppy Tim Work Though. Now We Can Keep An Keen Eye On These Heat Sinks Cause This Light Is Being Turn Over To My Beloved Vero29 Gen 7 B Version.Hard anodizing produce 30 micron layer if you respect the righ time of the process, if you are under, near 5/10 micron, probably too fast process, and a thin layer in teory can do that type o damage on prolonged exposure to heat and light.

Hard anodizing produce 30 micron layer if you respect the righ time of the process, if you are under, near 5/10 micron, probably too fast process, and a thin layer in teory can do that type o damage on prolonged exposure to heat and light.

Well Here's Some Food For Thought. The So Called Oxidation I

Is The Same Color As Copper So My Question Is Would You Notice it???

Sorry. Must have been stoned. But I actually meant slight ir?uv? At the endCheap anodize dye?

Probably heat + light intensity?

That being said, one of my heatsink is like that because it was next to a metal halide. The entire side of it changed to that color. It wasn't even close enough to cause it to heat up. So in my case it was likely the heat source.