No, The 120 is the wattage of the driver, the second number (36) is the voltage it provides the letter is the type of dimming.

Unless there is a C before the second number like 120h-c2100 , which means its constant current.

The constant voltage driver needs to be wired in parallel.

The constant current driver is wired in series and provides every board/strip the listed current.

The constant voltage driver puts out a total current which is divided by the amount of boards/strips in parallel connection.

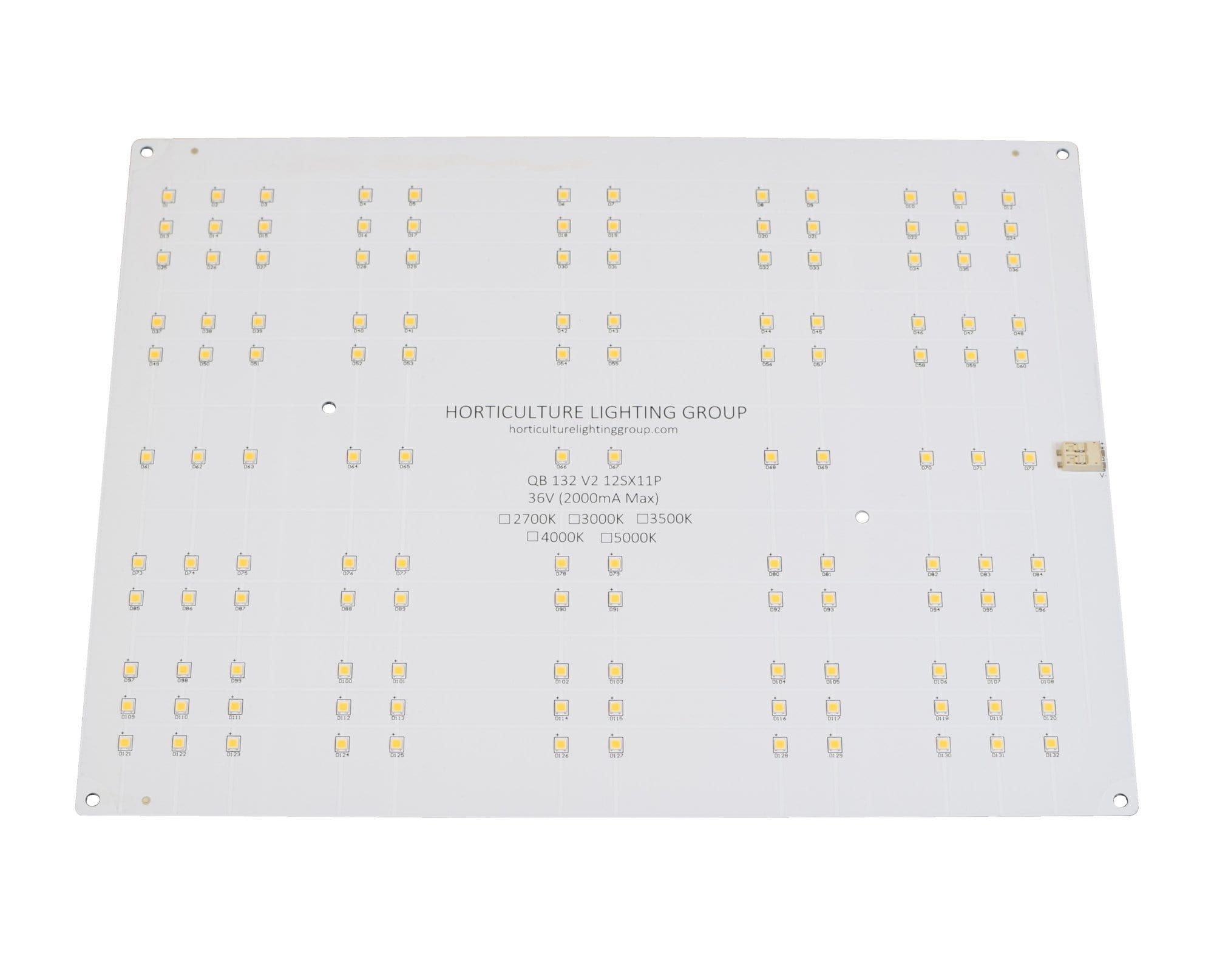

With the 120h-36a it will match the QB132 boards you were looking at.

MEAN WELL is one of the world's few standard power supply mainly professional manufacturers, covering 0.5 to 25,600W products are widely used in industrial control, medical and other fields, in line with international safety certification, short delivery of spot inventory.

www.meanwell.com

High Efficiency LED Light Engines. 132pcs Samsung LM301H LED per board

horticulturelightinggroup.com

Edit, you better link the exact boards on amazon because they may not be what I was talking about in the first place and its very important you match the driver to the boards , especially with constant voltage