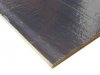

Aluminum foil is an excellent reflector for all radiance. It reflects radiant heat(IR:infrared) just like light, as both are electromagnetic. Bare mirror-finish aluminum(most foils are 92-99% pure Al) is up to 97% reflective for IR heat waves, and up to 91-92% for visible light. Foil is made by a process of combining two films into one. A large, smooth, polished roller on top, and an unpolished surface beneath meld them into a single film. This is responsible for imparting foil with the well-known near-mirror shiny polished look on one side, and a dull matte appearance on the other.

The side of the foil isn't significant for radiance blocking; however, the shiny side is highly specular and is superior at precisely reflecting light with a greater intensity. Crinkled, bubble-wrap type/insulation, foil is crinkled for the purpose of diffusion, so radiance is not reflected as intensely in any one direction. It is still highly effective. The crinkles do not significantly change the intrinsic reflective properties, but only the direction at which reflected photons(light, radiation) are sent.

Similar surfaces are seen in dimpled hoods, the purpose is the same, diffusion/scattering/spreading of light, usually used with a high-intensity(HID) source. Fluorescents are rarely found with dimpled hoods, as they reflect significantly less intense(concentrated) radiation, as they have a much wider, more even dispersion. As such are not ideal, as fluorescents themselves are not as intense. As any HID grower will tell you, "intensity is the bee's knee"(ok, maybe not exactly). Usually the idea is to concentrate the fluoro intensity to create a more viable, productive and intense light. Actually reflecting it back upon itself precisely and intensely, increasing lux significantly.

HID growers make hot spots, fluoro growers make sweet spots.