Grow Lights Australia

Well-Known Member

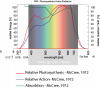

LED Teknik has just done a new round of efficiency and spectrum testing for us and we were surprised to see the 1A test report come back as 3.19 umol/j. Without blowing our own trumpet (OK, we are!) that's a pretty good efficiency figure for a "true" PAR+ full spectrum light. Especially considering there is 1% UVA and over 10% Far Red in there.

This is our Gen3 spectrum, which is 2900-3000K. The CCT changes as the current increases. Overall efficiency at each current setting is:

1A 3.19 umol/j

2A 3.01umol/j

3A 2.89 umol/j

4A 2.79 umol/j

5A 2.72 umol/j

System efficiency will be lower than LED efficiency and each of those figures falls to around 2.6-2.8 umol/j once connected to a driver that is 88-94% efficient. The lower the driver setting the more efficient the LEDs are but the less efficient the driver.

The most interesting thing about these tests was there has very little (less than 0.5%) difference between the uncoated and coated (waterproofed) panels. We don't use a typical silicon coating on our LED panels so we can apply it much thinner than 100% silicon.

We've been a bit quiet lately working on a few new things but I thought some people might be interested to know what we've been up to.

This is our Gen3 spectrum, which is 2900-3000K. The CCT changes as the current increases. Overall efficiency at each current setting is:

1A 3.19 umol/j

2A 3.01umol/j

3A 2.89 umol/j

4A 2.79 umol/j

5A 2.72 umol/j

System efficiency will be lower than LED efficiency and each of those figures falls to around 2.6-2.8 umol/j once connected to a driver that is 88-94% efficient. The lower the driver setting the more efficient the LEDs are but the less efficient the driver.

The most interesting thing about these tests was there has very little (less than 0.5%) difference between the uncoated and coated (waterproofed) panels. We don't use a typical silicon coating on our LED panels so we can apply it much thinner than 100% silicon.

We've been a bit quiet lately working on a few new things but I thought some people might be interested to know what we've been up to.