HandyGringo

Well-Known Member

I just thought I'd share this here since it's useful to me, so maybe it will be valuable to others too. Sometimes it's hard to have the ideal 60/60 environment for drying, I personally only have a furnace room for drying where the temperature is a bit too high, so I wanted to ensure that my dry was still done as well as possible.

I'm basing it mostly on this presentation:

The Science of Drying and Curing - By Allison Justice, PhD

And this study

Post-Harvest Operations to Generate High-Quality Medicinal Cannabis Products: A Systemic Review

But VPD for drying has been talked about by many more people, for instance, the creator of the Cannatrol also speaks of it and mirrors these same findings.

Anyway. In the above presentation, two interesting charts are presented.

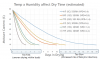

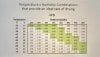

This chart, briefly summarizes which temps and humidities work for drying. Based on this, it seems like 0.8 - 1.1 kpA (VPD) is best for drying. Not too fast, not too slow.

Followed by this chart:

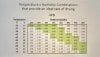

Which shows you some combinations that keep you in that ideal range. The only issue I have with this chart is that it's too narrow, too few combinations accounted for and I don't entirely understand how they calculated the VPD. Because for instance 25% RH and 13c give a kPa of 1.12 not 0.99. So if anyone can tell me why their VPD calculations are different that would be helpful.

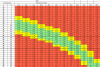

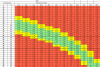

I made this chart, to expand it and I'm using the standard VPD calculations, highlighting the aforementioned 0.8 - 1.1 kPa range. Yellow are the values that are almost okay, but still, should aim for green. Red is a bad time all around. The HIGHER the kPa the quicker the dry.

A final note on terpenes. Based on the various studies on terpenes and their evaporation, 21c/70f is the temp where a few of them start evaporating (This is also spoken of in the presentation I linked above) - But a majority of terpenes don't start evaporating until 38c/100f.

It also seems like most of the studies into terpenes recommend drying in the 16c to 21c range (61f - 70f) - I'll be honest, I have no idea why I keep seeing a minimum temp like 18c or 16c mentioned. If anyone can elaborate on this and explain if there's any negative effect from drying at below 16c/61f I'd like to know. Because I can't seem to find any reasoning.

Perhaps it's because it's just cheaper and easier to dry at 16c to 21c, so that's what they tested with?

Anyway, thanks for reading, hope it can be useful for someone else than me. I also made a quick tool to input temp and humidity, will return the VPD and tell you if it's good for drying or not. But I feel like it's a bit redundant with the chart. But here's the link DryingVPD.

Please help me by correcting any mistakes or misunderstandings, because I'm no expert on any of this, this is just stuff I made for my use to help me dry.

I'm basing it mostly on this presentation:

The Science of Drying and Curing - By Allison Justice, PhD

And this study

Post-Harvest Operations to Generate High-Quality Medicinal Cannabis Products: A Systemic Review

But VPD for drying has been talked about by many more people, for instance, the creator of the Cannatrol also speaks of it and mirrors these same findings.

Anyway. In the above presentation, two interesting charts are presented.

This chart, briefly summarizes which temps and humidities work for drying. Based on this, it seems like 0.8 - 1.1 kpA (VPD) is best for drying. Not too fast, not too slow.

Followed by this chart:

Which shows you some combinations that keep you in that ideal range. The only issue I have with this chart is that it's too narrow, too few combinations accounted for and I don't entirely understand how they calculated the VPD. Because for instance 25% RH and 13c give a kPa of 1.12 not 0.99. So if anyone can tell me why their VPD calculations are different that would be helpful.

I made this chart, to expand it and I'm using the standard VPD calculations, highlighting the aforementioned 0.8 - 1.1 kPa range. Yellow are the values that are almost okay, but still, should aim for green. Red is a bad time all around. The HIGHER the kPa the quicker the dry.

A final note on terpenes. Based on the various studies on terpenes and their evaporation, 21c/70f is the temp where a few of them start evaporating (This is also spoken of in the presentation I linked above) - But a majority of terpenes don't start evaporating until 38c/100f.

It also seems like most of the studies into terpenes recommend drying in the 16c to 21c range (61f - 70f) - I'll be honest, I have no idea why I keep seeing a minimum temp like 18c or 16c mentioned. If anyone can elaborate on this and explain if there's any negative effect from drying at below 16c/61f I'd like to know. Because I can't seem to find any reasoning.

Perhaps it's because it's just cheaper and easier to dry at 16c to 21c, so that's what they tested with?

Anyway, thanks for reading, hope it can be useful for someone else than me. I also made a quick tool to input temp and humidity, will return the VPD and tell you if it's good for drying or not. But I feel like it's a bit redundant with the chart. But here's the link DryingVPD.

Please help me by correcting any mistakes or misunderstandings, because I'm no expert on any of this, this is just stuff I made for my use to help me dry.