Cannabis.Liberation.Army

Active Member

SUMMARY

Taste and combustion qualities of Cannabis are dependent on the chemical characteristics of the flower. These chemical characteristics can be influenced by management practices during the growing cycle. For this reason, many Cannabis growers implement a flushing period where only water is fed to plants in the final days to weeks before harvest. While many cultivators attest to the effects of a flush, no scientific studies have been conducted to validate this practice. Rx Green Technologies has undertaken a first of its kind study to determine the influence of different flushing times on the chemical profile, flavor, and combustion characteristics of Cannabis flower.

MATERIALS AND METHODS

Cannabis variety Cherry Diesel (Cherry OG x Turbo Diesel) was grown at the Rx Green Technologies R&D Facility using Rx Green Technologies nutrients and Clean Coco. Grow A, Grow B and E-Plus were fed during the vegetative stage and Bloom A, Bloom B, E-Plus, and Bulk were fed during the flowering cycle. The first flushing period began 14 days before harvest. The other flushing periods were ten, seven, and zero days before harvest. Each flushing period was tested on 12 different Cherry Diesel plants divided into four different groups (replications) spread evenly across the flowering room tables. Flower and fan leaf samples were collected from each flushing treatment the first day of flush and the day before harvest to quantify concentrations of essential plant nutrients. After harvest, trial plants were cured before determining final trimmed flower weight, terpene and THC concentrations. Trim was evaluated by an extractor for THC, yield, and appearance of the extract or “wax”.

To determine smoking flavor and characteristics, samples of each flushing period were distributed to Cannabis industry experts in a blind taste test. Each participant received one sample of each flushing time without knowledge of its treatment. Participants were asked about their personal Cannabis flavor preferences before tasting. After tasting, participants were asked to rate the sample for flavor, harshness of smoke, and color of ash.

Data collected during the course of the trial were analyzed statistically to determine whether flushing times affected smoking quality, flower weight, or chemical characteristics of Cannabis. Statistical analysis of data allows us to quantify whether differences in the numbers are due to the treatments imposed or are results of the natural variations observed when growing plants.

RESULTS AND DISCUSSION

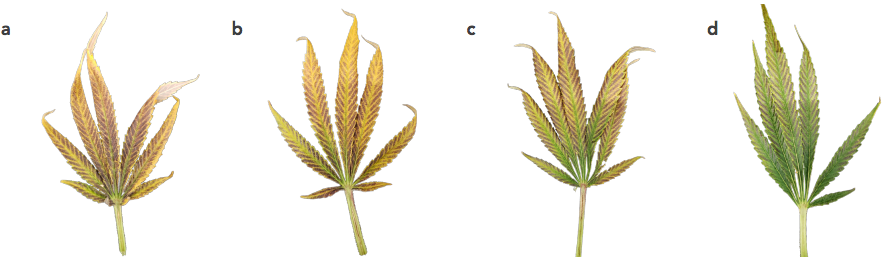

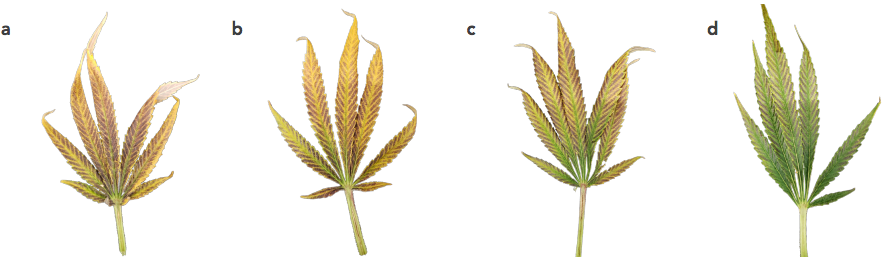

Visual differences in fan leaves between flushing times were apparent the day before harvest. Plants flushed for ten or 14 days had leaves that were more yellow, necrotic and dry than plants flushed for zero or seven days (Figure 1a-d). The color of the 14 and ten day flushed leaves indicates a greater breakdown of chlorophyll in the plant, leading to reduced greenness

Figure 1. Fan leaves collected from Cherry Diesel plants the day before harvest. Flushing times depicted are (a) 14 days, (b) 10 days, (c) 7 days, and (d) 0 days.

Yield, THC, and Terpenes

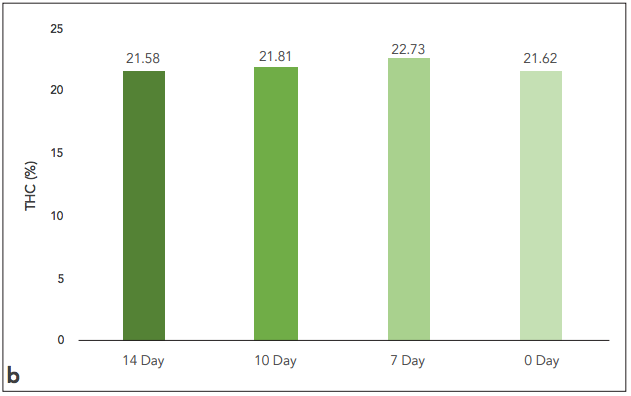

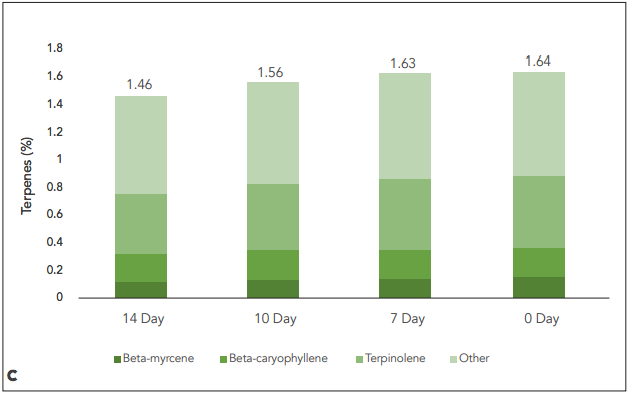

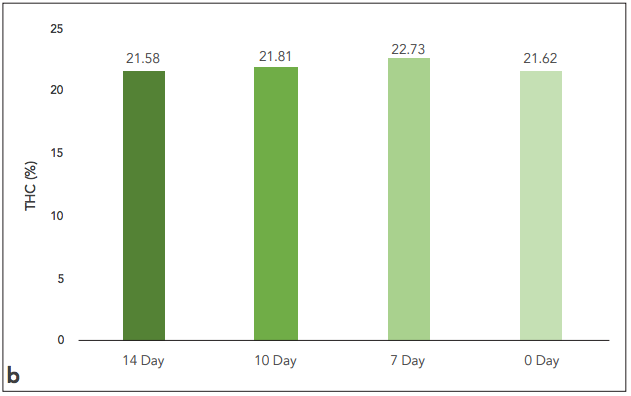

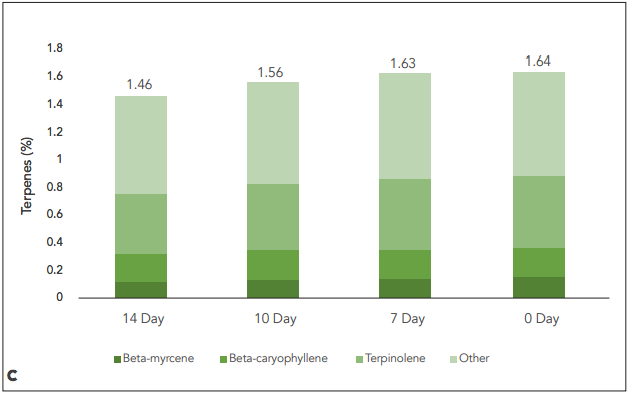

The flower weight, THC and terpene content of cured flower were determined for each flushing period. The data were analyzed statistically to determine whether the numerical differences in the data were due to the treatment. Overall, there were no significant differences between treatments for flower weight, THC or terpene content (Figure 2a-c) (P < 0.05). Flower weight per plant averaged 97.3 g and THC content averaged 21.9%. The dominant terpenes in the flower were beta-myrcene, beta-caryophyllene, and terpinolene, giving the flower an earthy and spicy smell (Figure 2c). Overall, flushing times did not impact flower weight, THC, or terpenes in Cherry Diesel.

Figure 2. Flower weight (a), THC (b) and terpene content (c) for Cherry Diesel flushed for 14, 10, 7 or 0 days before harvest. Significant differences are indicated at the 0.05 probability level.

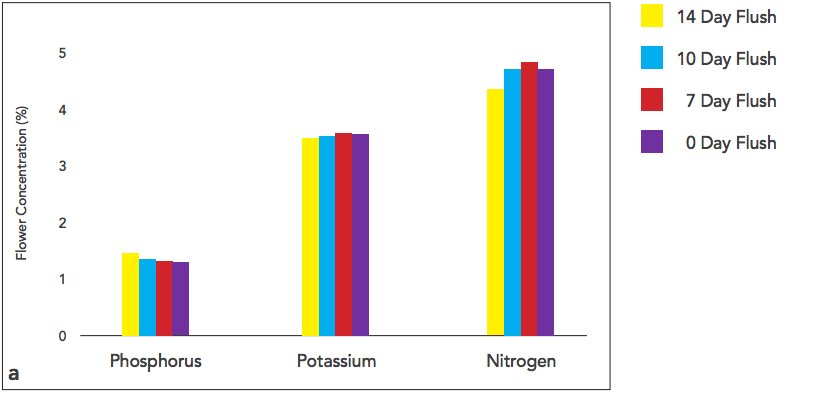

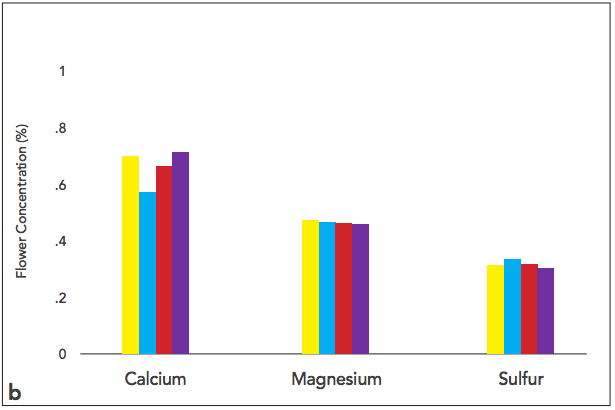

Mineral Content of Flowers at Harvest

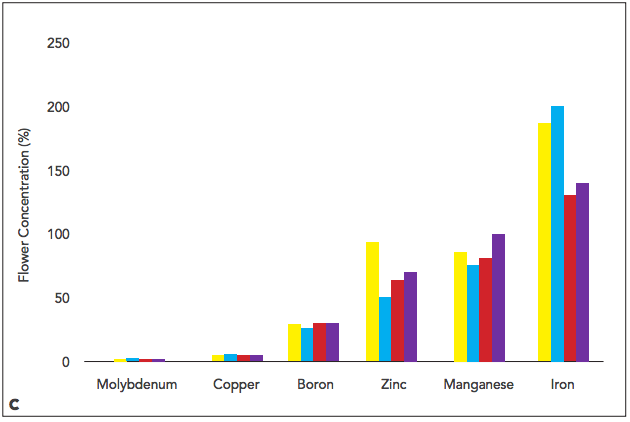

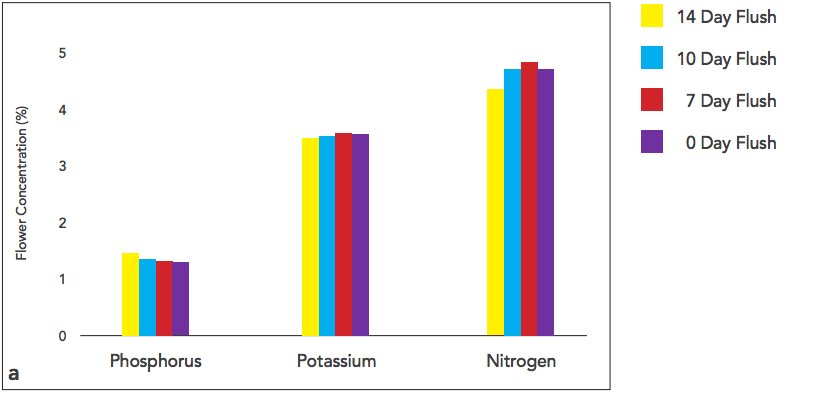

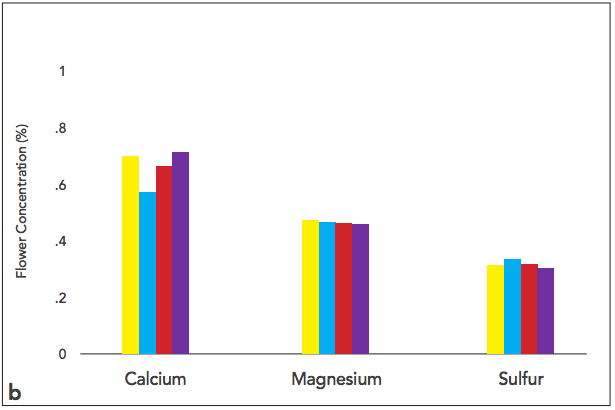

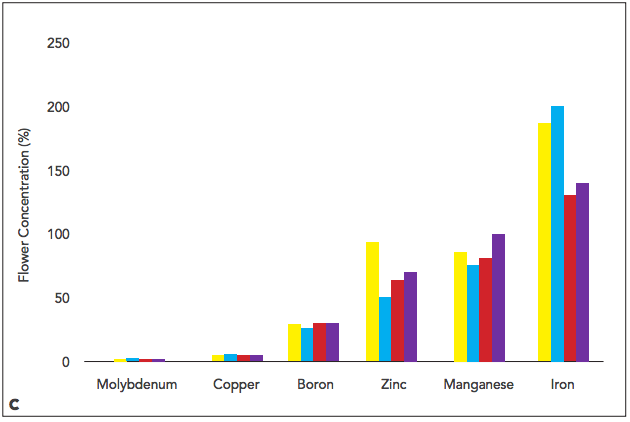

Flower samples taken the day before harvest were analyzed for content of essential plant nutrients. Overall, there was no significant change in the mineral content of flower as a result of different flushing treatments (Figure 3). In Cannabis flushed for 14 days, nitrogen was 6.7% lower than the zero-day flush treatment (Figure 3a). Continuing to feed nitrogen can increase its concentration in the plant, reducing the need for the plant to use its reserves for essential functions. Phosphorus, potassium, calcium, magnesium, and sulfur were similar for all four flushing treatments (Figure 3a-b).

There were changes in iron concentrations due to flushing treatments. Iron was at least 50 ppm higher in flower flushed for 14 or ten days (Figure 3c). Small changes were observed for zinc as well. Zinc was approximately 73 ppm higher in flower flushed for 14 days. The fluctuation in zinc did not follow a consistent pattern like iron. There was no significant change in manganese, boron, copper or molybdenum (Figure 3c). Nutrients like iron and zinc can accumulate in growing media over time. Feeding water during a flush may release some of these nutrients from the media into the plant. Additionally, zinc and iron are involved in the breakdown of chlorophyll occurring during senescence.

Data generated from plant parts, whether it be nutrient or THC concentrations, is naturally variable as only small samples of plants are consumed in the analysis. This may explain some of the variation seen in the data presented here. In other crops, ranges exist which indicate whether nutrient concentrations in leaves are deficient or sufficient for growth. All nutrient concentrations detected in this study are within generally accepted ranges of leaf concentrations for each nutrient. Toward the end of the Cannabis flowering cycle, the plant starts to naturally senescence. Plants that are nearing the end of their life cycle will uptake fewer nutrients as they remobilize nutrients from other plant parts. This may explain why little difference was observed in the mineral content of flower flushed for different times.

CONCLUSION

In a first of its kind study, Rx Green Technologies evaluated the effects of flushing period on yield, potency, terpenes, mineral content, and taste characteristics of Cannabis flower. Overall, the length of the flushing period did not impact yield, potency, terpenes, or taste characteristics of Cannabis flower. Taste test results indicated a trend toward improved flavor and smoke quality with the zero-day flush. While there were no significant differences in nutrient content, there was a trend toward increased iron and zinc in flower flushed for 14 days. The results of this trial indicate that there is no benefit to flushing Cannabis flower for improved taste or consumer experience.

www.rxgreentechnologies.com

www.rxgreentechnologies.com

- Rx Green Technologies evaluated the effects of different flushing times on chemical profile, flavor, and smoking characteristics in Cannabis flower.

- Flushing periods of 14, 10, 7 and 0 days were imposed on Cherry Diesel.

- No differences were detected between flush treatments for yield, potency, or terpenes.

- Analysis of mineral content of leaves indicated small changes in content of iron and zinc.

- Taste test panelists tended to prefer flower flushed for 0 days.

Taste and combustion qualities of Cannabis are dependent on the chemical characteristics of the flower. These chemical characteristics can be influenced by management practices during the growing cycle. For this reason, many Cannabis growers implement a flushing period where only water is fed to plants in the final days to weeks before harvest. While many cultivators attest to the effects of a flush, no scientific studies have been conducted to validate this practice. Rx Green Technologies has undertaken a first of its kind study to determine the influence of different flushing times on the chemical profile, flavor, and combustion characteristics of Cannabis flower.

MATERIALS AND METHODS

Cannabis variety Cherry Diesel (Cherry OG x Turbo Diesel) was grown at the Rx Green Technologies R&D Facility using Rx Green Technologies nutrients and Clean Coco. Grow A, Grow B and E-Plus were fed during the vegetative stage and Bloom A, Bloom B, E-Plus, and Bulk were fed during the flowering cycle. The first flushing period began 14 days before harvest. The other flushing periods were ten, seven, and zero days before harvest. Each flushing period was tested on 12 different Cherry Diesel plants divided into four different groups (replications) spread evenly across the flowering room tables. Flower and fan leaf samples were collected from each flushing treatment the first day of flush and the day before harvest to quantify concentrations of essential plant nutrients. After harvest, trial plants were cured before determining final trimmed flower weight, terpene and THC concentrations. Trim was evaluated by an extractor for THC, yield, and appearance of the extract or “wax”.

To determine smoking flavor and characteristics, samples of each flushing period were distributed to Cannabis industry experts in a blind taste test. Each participant received one sample of each flushing time without knowledge of its treatment. Participants were asked about their personal Cannabis flavor preferences before tasting. After tasting, participants were asked to rate the sample for flavor, harshness of smoke, and color of ash.

Data collected during the course of the trial were analyzed statistically to determine whether flushing times affected smoking quality, flower weight, or chemical characteristics of Cannabis. Statistical analysis of data allows us to quantify whether differences in the numbers are due to the treatments imposed or are results of the natural variations observed when growing plants.

RESULTS AND DISCUSSION

Visual differences in fan leaves between flushing times were apparent the day before harvest. Plants flushed for ten or 14 days had leaves that were more yellow, necrotic and dry than plants flushed for zero or seven days (Figure 1a-d). The color of the 14 and ten day flushed leaves indicates a greater breakdown of chlorophyll in the plant, leading to reduced greenness

Figure 1. Fan leaves collected from Cherry Diesel plants the day before harvest. Flushing times depicted are (a) 14 days, (b) 10 days, (c) 7 days, and (d) 0 days.

Yield, THC, and Terpenes

The flower weight, THC and terpene content of cured flower were determined for each flushing period. The data were analyzed statistically to determine whether the numerical differences in the data were due to the treatment. Overall, there were no significant differences between treatments for flower weight, THC or terpene content (Figure 2a-c) (P < 0.05). Flower weight per plant averaged 97.3 g and THC content averaged 21.9%. The dominant terpenes in the flower were beta-myrcene, beta-caryophyllene, and terpinolene, giving the flower an earthy and spicy smell (Figure 2c). Overall, flushing times did not impact flower weight, THC, or terpenes in Cherry Diesel.

Figure 2. Flower weight (a), THC (b) and terpene content (c) for Cherry Diesel flushed for 14, 10, 7 or 0 days before harvest. Significant differences are indicated at the 0.05 probability level.

Mineral Content of Flowers at Harvest

Flower samples taken the day before harvest were analyzed for content of essential plant nutrients. Overall, there was no significant change in the mineral content of flower as a result of different flushing treatments (Figure 3). In Cannabis flushed for 14 days, nitrogen was 6.7% lower than the zero-day flush treatment (Figure 3a). Continuing to feed nitrogen can increase its concentration in the plant, reducing the need for the plant to use its reserves for essential functions. Phosphorus, potassium, calcium, magnesium, and sulfur were similar for all four flushing treatments (Figure 3a-b).

There were changes in iron concentrations due to flushing treatments. Iron was at least 50 ppm higher in flower flushed for 14 or ten days (Figure 3c). Small changes were observed for zinc as well. Zinc was approximately 73 ppm higher in flower flushed for 14 days. The fluctuation in zinc did not follow a consistent pattern like iron. There was no significant change in manganese, boron, copper or molybdenum (Figure 3c). Nutrients like iron and zinc can accumulate in growing media over time. Feeding water during a flush may release some of these nutrients from the media into the plant. Additionally, zinc and iron are involved in the breakdown of chlorophyll occurring during senescence.

Data generated from plant parts, whether it be nutrient or THC concentrations, is naturally variable as only small samples of plants are consumed in the analysis. This may explain some of the variation seen in the data presented here. In other crops, ranges exist which indicate whether nutrient concentrations in leaves are deficient or sufficient for growth. All nutrient concentrations detected in this study are within generally accepted ranges of leaf concentrations for each nutrient. Toward the end of the Cannabis flowering cycle, the plant starts to naturally senescence. Plants that are nearing the end of their life cycle will uptake fewer nutrients as they remobilize nutrients from other plant parts. This may explain why little difference was observed in the mineral content of flower flushed for different times.

CONCLUSION

In a first of its kind study, Rx Green Technologies evaluated the effects of flushing period on yield, potency, terpenes, mineral content, and taste characteristics of Cannabis flower. Overall, the length of the flushing period did not impact yield, potency, terpenes, or taste characteristics of Cannabis flower. Taste test results indicated a trend toward improved flavor and smoke quality with the zero-day flush. While there were no significant differences in nutrient content, there was a trend toward increased iron and zinc in flower flushed for 14 days. The results of this trial indicate that there is no benefit to flushing Cannabis flower for improved taste or consumer experience.

Cannabis Flushing Study on Grow Nutrients I Rx Green

Rx Green’s research study on cannabis flushing explores the truth behind this urban myth in growing nutrients.