You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Samsung F562B Linear Strip Build

- Thread starter Takeshy

- Start date

Warpedpassage

Well-Known Member

Nope, I recommend parallel wiring for electro noobs to reduce the risk to get deathly electro shocked! The good thing about Meanwell's HLG drivers is that even the -48A can run in constant current mode as long as the voltage is below 48v (24-48v CC range). Therefor they are called CV/CC.

But with parallel wiring there is always an uneven distribution because of minor difference in voltage and resistance. The strip/COB/LED's with the lowest voltage/resistance sucks always the most current. The differences are most probably not visible to the naked eye, because the differences are small these days, but they are there.

In a worst case scenario you could get thermal runaways with parallel wiring. The risk is higher the more LED's are added in parallel.

BUT, all the CV/CC A-drivers have an additional voltage regulator that allows regulation between 43-53v. If you set the voltage limit to 47 or 48v, the probability of failure by thermal runaways equals near to zero!

But which voltage limit to use depends on the current one strip/COB/LED get.

The voltage limit should be selected based on the data sheet of the LED's. Calculate how much current the LED gets at which voltage from the selected driver (driver current divided by number of parallel LED's) and select a limit just above this voltage, because when switching on, the voltage is always slightly higher! +1v is enough!

If you have no datasheet at hand reduce the voltage untill the lights starts getting visible darker and set the voltage just above that point. Dimming is realized only about the second regulator, which regulates the current!

For my own builds I still prefer series wiring(less wiring effort, more possibillities, no need for failure protection like setting voltage limits) but based on this background above it really doesn't matter which way one goes! Both will work!

Thank you for all the help.

In a previous post you mentioned that the hlg 240h 48a can max out at 280w. So running 4 single samsung f strips on this driver could deliver up to 70 watts per strip relatively safely in parallel? Using wagos.

Randomblame

Well-Known Member

Thank you for all the help.

In a previous post you mentioned that the hlg 240h 48a can max out at 280w. So running 4 single samsung f strips on this driver could deliver up to 70 watts per strip relatively safely in parallel? Using wagos.

HLG-240H-48A has 5,2A on the datasheet but maxed-out with up to 5,5A or ~265w, add 6% driver loss(94% effiency) and he sucks 281w from the wall. With 4 strips in parallel each would get 1375mA, thats 255mA above nominal current and the one strip needs 47 or more volts corresponding to the datasheet. Thats ~260w net, ~276w total.

With 1"aluminum c-channels/u-profiles as heatsinks the temps should stay in the 50°C range. Double sided thermal tape is relatively cheap(e3ay, 25m rolls, 20mm wide, 0,2mm thickness costs around 8$) and is sticky like hell.

https://www.ebay.com/itm/0-2mm-Thic...m=162873467291&_trksid=p2047675.c100005.m1851

Last edited:

Warpedpassage

Well-Known Member

HLG-240H-48A has 5,2A on the datasheet but maxed-out with up to 5,5A or ~265w, add 6% driver loss(94% effiency) and he sucks 281w from the wall. With 4 strips in parallel each would get 1375mA, thats 255mA above nominal current and the one strip needs 47 or more volts corresponding to the datasheet. Thats ~260w net, ~276w total.

With 1"aluminum c-channels/u-profiles as heatsinks the temps should stay in the 50°C range. Double sided thermal tape is relatively cheap(e3ay, 25m rolls, 20mm wide, 0,2mm thickness costs around 8$) and is sticky like hell.

https://www.ebay.com/itm/0-2mm-Thick-25M-Roll-LED-HeatSink-Double-Sided-Adhesive-Thermal-Transfer-Tape-LY/162873467291?_trkparms=aid=555018&algo=PL.SIM&ao=2&asc=44039&meid=62e6da66c4db491f8e79f7dd91539baa&pid=100005&rk=3&rkt=6&sd=262181142693&itm=162873467291&_trksid=p2047675.c100005.m1851

I swear you have the patience of a saint!!! I cant help it wonder if you are educator of some sort. Anyhow, many thanks.

Warpedpassage

Well-Known Member

My copy of the datasheet says 5A?

I was wondering about that as well.

Randomblame

Well-Known Member

Sorry, bros! A typo!

Tse! I slowly getting old, lol!

Tse! I slowly getting old, lol!

T-Time

Well-Known Member

Maybe someone could help brother out

I'm looking to build light fixture for a friend.

16x SI-B8V521560WW to be put on two seperate drivers. Would be used to flower in 1.5m x 0.9m space (5'x3')

Two questions:

1) 2x 185h-48a , 240h-48a or maybe 320h-48a ?

2) what size of C channel alu would be sufficient to cool it off ?

Edit:

Do I get it right, if I use 240h-48a it will switch to CC mode and give 8 strips connected in parallel 5A /8 strips = 625mA each ? Nominal current for those strips is 1120mA so i would be just running them more efficient or theres something else I'm missing here ?

I'm looking to build light fixture for a friend.

16x SI-B8V521560WW to be put on two seperate drivers. Would be used to flower in 1.5m x 0.9m space (5'x3')

Two questions:

1) 2x 185h-48a , 240h-48a or maybe 320h-48a ?

2) what size of C channel alu would be sufficient to cool it off ?

Edit:

Do I get it right, if I use 240h-48a it will switch to CC mode and give 8 strips connected in parallel 5A /8 strips = 625mA each ? Nominal current for those strips is 1120mA so i would be just running them more efficient or theres something else I'm missing here ?

Last edited:

Randomblame

Well-Known Member

Maybe someone could help brother out

I'm looking to build light fixture for a friend.

16x SI-B8V521560WW to be put on two seperate drivers. Would be used to flower in 1.5m x 0.9m space (5'x3')

Two questions:

1) 2x 185h-48a , 240h-48a or maybe 320h-48a ?

2) what size of C channel alu would be sufficient to cool it off ?

Edit:

Do I get it right, if I use 240h-48a it will switch to CC mode and give 8 strips connected in parallel 5A /8 strips = 625mA each ? Nominal current for those strips is 1120mA so i would be just running them more efficient or theres something else I'm missing here ?

Hey T-Time, let me try!

Q1. 1,5 x 0,9m is 1,35m² or ~14,5sft, 14,5 x 35w = 507,5w. So based on the 35w/sft rule 2 HLG-240H-48A would be sufficient(2x ~280w at the wall)!

Q2. 25x 40x 25x 2mm c-channel is more than enough, especially when the strips are running only at almost half the cuurent. I'm pretty sure you could do it even without heatsinks.

But at least he could upgrade to bigger drivers later, when he decide to use a bigger tent or so.

And no, you missed nothing. At 625mA one strip needs ~45v and there should be no issues with the 48v driver, no matter if it run in CC or CV mode. It should use CC mode below 48v but 45v is also in the voltage regulation range and you could limit the voltage to lets say ~46v to avoid the risk of thermal runaways. But I see no reason for such a limit because of the low current each strip gets.

There would have to be a significant voltage/resistance difference to cause thermal runaways. But that's not to be expected, because the stripes have almost identical voltage values.

I estimate it ~ 184lm/w or 2.7μmol/J net., that would be about 2.5μmol/J at system level (minus driver and wall loss).

BTW,

you can easily find out in which mode the drivers are running.

If you turn the voltage regulator counterclockwise and there are no brightness changes, the drivers will run in CC mode. If you turn it and it gets darker it will run in CV mode. The voltage poti is disabled in CC mode.

Last edited:

T-Time

Well-Known Member

Hey T-Time, let me try!

Q1. 1,5 x 0,9m is 1,35m² or ~14,5sft, 14,5 x 35w = 507,5w. So based on the 35w/sft rule 2 HLG-240H-48A would be sufficient(2x ~280w at the wall)!

Q2. 25x 40x 25x 2mm c-channel is more than enough, especially when the strips are running only at almost half the cuurent. I'm pretty sure you could do it even without heatsinks.

But at least he could upgrade to bigger drivers later, when he decide to use a bigger tent or so.

And no, you missed nothing. At 625mA one strip needs ~45v and there should be no issues with the 48v driver, no matter if it run in CC or CV mode. It should use CC mode below 48v but 45v is also in the voltage regulation range and you could limit the voltage to lets say ~46v to avoid the risk of thermal runaways. But I see no reason for such a limit because of the low current each strip gets.

There would have to be a significant voltage/resistance difference to cause thermal runaways. But that's not to be expected, because the stripes have almost identical voltage values.

I estimate it ~ 184lm/w or 2.7μmol/J net., that would be about 2.5μmol/J at system level (minus driver and wall loss).

BTW,

you can easily find out in which mode the drivers are running.

If you turn the voltage regulator counterclockwise and there are no brightness changes, the drivers will run in CC mode. If you turn it and it gets darker it will run in CV mode. The voltage poti is disabled in CC mode.

Thank You Green Tooth for that

I'm still learning electric stuff and only starting to getting my head around the topic.

I'm looking at the option of using 320h-48a just for the sake of better efficiency (95% vs 93% ) and upgradability in the future. Theres always option to turn it down a bit when needed.

If I can get a hand of F564b in 5000k I might as well put 8 of those those on one driver and 8 of 3000k on the other, so he would have an option to veg with the light and have mixed spectrum for the flower which might improve quality/speed things up a bit.

Whay would be Your take on that ?

Randomblame

Well-Known Member

Would work well, with 25x 40x 25mm C-channels you could use a HLG-480H-48A without getting issues. Samsungs strip tests are done without heatsink and they measured 65°C @1120mA on the center measuring point. With c-channels it would be 10-15°C less.

A 5000/3000°k mix would give you even more control over stature and nodial spacings.

2700 + 4000°k can be used in the same way, but would deliver a bit more red. After all, the vegging is usually much shorter and the lights are mainly made for flowering purposes.

If we look at YPF/w performance the lower kelvins are more efficient.

A 5000/3000°k mix would give you even more control over stature and nodial spacings.

2700 + 4000°k can be used in the same way, but would deliver a bit more red. After all, the vegging is usually much shorter and the lights are mainly made for flowering purposes.

If we look at YPF/w performance the lower kelvins are more efficient.

T-Time

Well-Known Member

Would work well, with 25x 40x 25mm C-channels you could use a HLG-480H-48A without getting issues. Samsungs strip tests are done without heatsink and they measured 65°C @1120mA on the center measuring point. With c-channels it would be 10-15°C less.

A 5000/3000°k mix would give you even more control over stature and nodial spacings.

2700 + 4000°k can be used in the same way, but would deliver a bit more red. After all, the vegging is usually much shorter and the lights are mainly made for flowering purposes.

If we look at YPF/w performance the lower kelvins are more efficient.

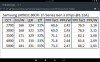

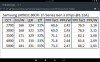

View attachment 4125456

I think I'm gonna stick with 2x 320h-48a with 3000k all the way as the 5000k are hard to get.

Thanks for the help. I'll post the build when its done

T-Time

Well-Known Member

Yes.can the F562B be used for both veg and flower ?

If You want veg light only pick 5000K and 3000k for flower only. 3500k is a good compromise that will give You a good results for both if You're planning one light to do it all.

Similar threads

- Replies

- 2

- Views

- 791

- Replies

- 9

- Views

- 725

- Replies

- 1

- Views

- 678

- Replies

- 0

- Views

- 346