Can i use this tape to attach my strips?

- Thread starter Kaneh_bosm

- Start date

BuddyColas

Well-Known Member

Yes. I am always trying different spacing and coverages, so all my builds are a "test." But, tape is all I have used. I must say using Kapton tape on white or silver sheet metal looks a little ghetto, but it works great. You don't need any thermal grease. Clear tape, like you have, should work great. Just check the strips from time to time to see if the strips are still flat and snug against the heatsink.View attachment 4047095 Permanent doesnt scare me, its free. part number 4010.

As an aside, my original LED DIY build using long finned extruded heatsinks and Vero 29s, well the COBS were installed with Kapton tape. And 3 years later, still working great. I credit Supra for the Kapton tape mounting idea.

Last edited:

Kaneh_bosm

Well-Known Member

thanks man now i can proceed. Happy ThanksgivingYes. I am always trying different spacing and coverages, so all my builds are a "test." But, tape is all I have used. I must say using Kapton tape on white or silver sheet metal looks a little ghetto, but it works great. You don't need any thermal grease. Clear tape, like you have, should work great.

BuddyColas

Well-Known Member

The real test to see if you are dissipating enough heat using your tape mounted strips is to check voltage droop on your strips.thanks man now i can proceed. Happy Thanksgiving

BTW, cobs do need thermal grease, strips do not.

Last edited:

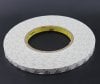

That Scotch mounting tape will work, but I don't think it will conduct heat well. I use this thermally conductive tape...

https://www.ebay.com/itm/0-2mm-Thick-25M-Roll-LED-HeatSink-Double-Sided-Adhesive-Thermal-Transfer-Tape/252440286967?hash=item3ac69d16f7:m:mMU4RGpHD6AaQZUKllZxikw

https://www.ebay.com/itm/0-2mm-Thick-25M-Roll-LED-HeatSink-Double-Sided-Adhesive-Thermal-Transfer-Tape/252440286967?hash=item3ac69d16f7:m:mMU4RGpHD6AaQZUKllZxikw

psychedelicdaddi

Well-Known Member

Op's tape would probably melt a bit and you'd be dropping lights soon after

thermal adhesive ftw, but be careful applying because it is a strong bond that is tough to undo without some practice.

thermal adhesive ftw, but be careful applying because it is a strong bond that is tough to undo without some practice.

BuddyColas

Well-Known Member

The Scotch mounting tape only holds the strip to the sink. The back of the strip is in full contact with the heatsink. I am running EB ver. 1 strips at 75% of max. (1.05a) and it works great. About 1.5% voltage droop max.That Scotch mounting tape will work, but I don't think it will conduct heat well. I use this thermally conductive tape...

https://www.ebay.com/itm/0-2mm-Thick-25M-Roll-LED-HeatSink-Double-Sided-Adhesive-Thermal-Transfer-Tape/252440286967?hash=item3ac69d16f7:m:mMU4RGpHD6AaQZUKllZxikw

BuddyColas

Well-Known Member

Im talking single sided. You are right for double sided. That goes between the strip and the sink.Double sided mounting tape is intended to go between two objects... how does that put the back of the strip in full contact with the heat sink?

VegasWinner

Well-Known Member

https://www.amazon.com/Rextin-Meters-Double-Adhesive-Lights/dp/B00N7D62HC

try this tape it is used for 505 smd leds.

Danielson999

Well-Known Member

Like others have said, don't use the tape you showed a picture of. You need double sided thermal tape. It's cheap and works great. I have a fixture that has 6 1120mm strips held only by the cheap double sided tape and they are on there really good. Infact, I had to use a putty knife to get one or two off.