Day 30 (L1-L3) update. As you look down the trailers you'll see that we have 5 lights with 3 of them(L1-L3) set up on UV-Pontoons with L4/5 running with straight LED and no Pontoons. Also the plants under L4/5 are at day 14 of flower and they are all in Growpito spun rock media, not the coco-soil mixes you can see under lights L1-L3. I think you can see for yourself that the Growpito as it is bottom fed is getting much better aeration in those buckets. The L4/5 plants are fatter and healthier from what I can see out of those plants in the coco-soil mix. It's not that the coco plants aren't looking good but I can definitely see that the Growpito plants are farther along in plant size at 1/2 the time. In these image you'll also see the main electric panel and the controls bypass switch. This is a simple way of using the toggle switch mounted on the side of the electric panel to move main lighting control over to a 24 hour analog timer if there are ever any issues with your tablet connectivity or should you have a systems glitch.

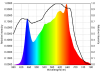

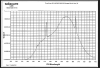

The entire system including a propagation/veg area and 2 ton 13 seer mini-split is ran off of a 2 pole 60 amp circuit breaker. At no time does that main circuit ever exceed 40 amps per pole. The flowering trailer with all the lights running in full flower setting with the 3 attachment UV-Pontoons consumes a total of 3900 watts. The thermal contribution from the lights is 13,300 btu/hr which for our 2 ton mini-split rated @ 24,000 btu capacity is not a problem at all. The flowering bed measures 4' x 25' = 100 sq-ft total area or 39 watts per sq-ft of lighting load as currently configured.

Keeping in mind that these are not ideal environmental conditions in that the trailer is not insulated and we're not using supplemental CO2 we have factored these low end production values at:

1 plant/sq-ft at low end production of 2 oz per plant this would come to 200 oz (12.5 lbs or 5600 grams) of top shelf quality in a 7 week finish. This extrapolates out to 1.43 grams per watt or 56 grams per sq-ft.

These are worse case scenarios. The other thing to consider in reducing costs would be our controller which can run every other light at a checkerboard feature. What this does is take L1, L3 and L5 lights to 100% output for 30 minutes while L2 and L4 run at say 50% output. Every 30 minutes the controller will flip that so that L2 and L4 will run at 100% and L1, L3 and L5 may only drop down to lay 70% output. These are ALL user defined settings. The bottom line is you've just cut your electric bill down by 20-30% and you've reduced your thermal contribution within the room.