PoDunk

Active Member

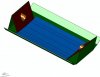

This is what I have made so far. It is made out of aluminum. I wanted to put two 400w bulbs in it. One on each side. One is MH the other is an HPS conversion bulb. I tried to polish it before bending. It is not a mirror finish. More like a dull mirror. Does anyone think that is good enough or should I sand and polish to a mirror finish? Kinda hard now that it is already bent.

The top is 12" across before it starts to bend. Just over 26" long the other direction. I might go to a siding retailer to get the dimpled aluminum.

I have taken the ballast off of one of my high bay fixtures. It is actually pretty easy to do. I have not extended the wires yet but it looks pretty straight forward. After I got it apart I tested it out with the bulb standing straight up. Don't do that. They get real hot and start to burn.

Don't do that. They get real hot and start to burn.

Feel free to pick it apart. I can make another one or modify this one to get it right. Maybe slot the top to let heat out? Fire away...

The top is 12" across before it starts to bend. Just over 26" long the other direction. I might go to a siding retailer to get the dimpled aluminum.

I have taken the ballast off of one of my high bay fixtures. It is actually pretty easy to do. I have not extended the wires yet but it looks pretty straight forward. After I got it apart I tested it out with the bulb standing straight up.

Feel free to pick it apart. I can make another one or modify this one to get it right. Maybe slot the top to let heat out? Fire away...